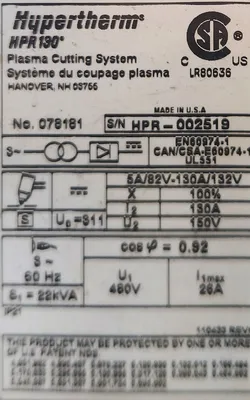

It's a 6' x 12' table with really nice downdraft design. The collection bucket follows directly under the torch head. Absolutely no smoke in the shop. 130-amp all Hypertherm components: HPR-130XD, Autogas, Arcglide height control, touch screen control. Microair dust collector with two sets of filters. New in 2008 and fully upgraded in 2013. Lightly used for mostly sheet metal and some plate. Cuts up to 1" steel, 1/2" stainless steel & aluminum. Super clean cuts for a plasma cutter

Dual side drive. This makes it cut really square as long as the limit switches are set right. I calibrate them about twice a year.

Upgrade: EdgeTi touch screen controller, ArcGlide height control, drive motors, gas metering console, XD power supply and XD Torch. Basically all new electronics. The upgrade made a huge boost to performance and cut quality.

Holes are decent, but not bolt quality. Edge quality is very good across the board.

480V 3-phase. Transformer included to go from 208V up to 480V.

The nicest feature of the table is the downdraft. It's one-of-a-kind. The collection bucket follows the torch so the fumes are almost completely removed even though the table is open on top. Most downdraft tables are zoned and you have to cover the open area in order to suck up the fumes.

All maintained perfectly. Stored indoors. Lightly used. The plasma worked really well when I was cutting mostly steel and aluminum. It puts too much heat into the stainless thin parts I'm making now. I miss the plasma for plate cutting. It was so nice. My new laser demands high quality steel to cut properly.

We use cookies to improve your experience. Privacy Policy.