7 - AxisTWIN-SPINDLE MILL TURN CENTER WITH “Y” Axis & DUAL “C” AXIS

Main Spindle:

Maximum RPM / spindle bearing 6,000 RPM / 5-bearing spindle, 3-front, 2-rear

Spindle Motor 10-HP 3,000 rpm spindle motor, 2:1 pulley ratio

Collet Nose Brown & Sharpe #22 or Traub A-32

Drawtube Bore 1.456”

Maximum Barstock Diameter 1.25”standard 1.375” with adapter

Barstock Preparation Above34mm with 36mm adapter

X-axis Travel 7.28”

Y-axis Travel (true Y-axis, not compound Y) 19.29”

Z-axis Travel 6.50”

Rapid Travel Speed: X, Y, Z 1,181IPM

Minimum input unit 40millionths (0.00004”)

OD Turning Tool Positions 6OD Tools (½” ) (5-5/8” tool plate available)

ID Turning Tool Positions 5ID Tools

OD Turning Tool size ½”or 12mm (5/8”or Optional)

ID Turning Tool Bore Size 25mm

Spindle Center Height 40”

SubSpindle:

Sub spindle RPM / spindle bearing 6,000RPM / 4-bearing Quad-Duplex pair configuration

Sub spindle Motor 5-HP3,000 rpm spindle motor, 2:1 pulley ratio

Collet Nose Brown& Sharpe #22 or Traub A-32

Maximum Barstock Diameter 1.250”in collet chuck (1.080” pass thru)

X-axis Travel 11.53”

Z-axis Travel 11.61”

Minimum input unit 0.0001”

ID Turning Tool Bore Size 25mm

Air Blast nozzle Included

Finished Parts Ejector Included,along with parts catcher & parts conveyor belt

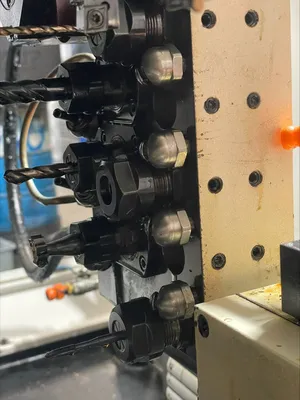

Live Tooling: All live tools are gear driven w/ ø42mm bearings – no belts!

Cross slide live tools 4-ER-20cross slide live tools, 4,000 rpm, 2.0 HP (1.5kw)

Front slide live tools 3-ER-20front slide live tools, 4,000 rpm, 1.0 HP (0.75kw)

Live tool collet size ER-20collet, Ø1/2” (0.5-13mm) tool shank capacity

Max RPM for live tools 4,000RPM (1cross live tool can be substituted on subspindle tool block)

Machine Dimensions:

Machine Length 101” * ( * +36” for chip conveyor)

Machine Depth 68”

Machine Height 80”

Machine Weight 8,000lbs

Coolant Pump Dual50psi 3/4-HP Coolant Pumps for main and subspindle

Coolant Tank Capacity 63-galloncoolant tank, with coolant flow confirmation sensor

Lubrication distribution Waylube distributed at 3-6 cc / 15-minute cycle

Machine Power Requirements 220vac±5%, 63-amps, 3-phase, 60Hz

Air Requirements 85-PSIat 10-CFM for parts catcher, parts ejector, & air blast

Machines need stable 220 Volts, 3 Phase – Please use appropriate transformers voltage stabilizers

Mist Buster

LNS Chip Conveyor

Fire Suppressor

We use cookies to improve your experience. Privacy Policy.